Products

Multi-layer deposition system for manufacture

AFTEX-8000Series

Solid-source ECR plasma deposition system that makes it possible to form multi-layer films from a large number of materials.

- Low temperature process

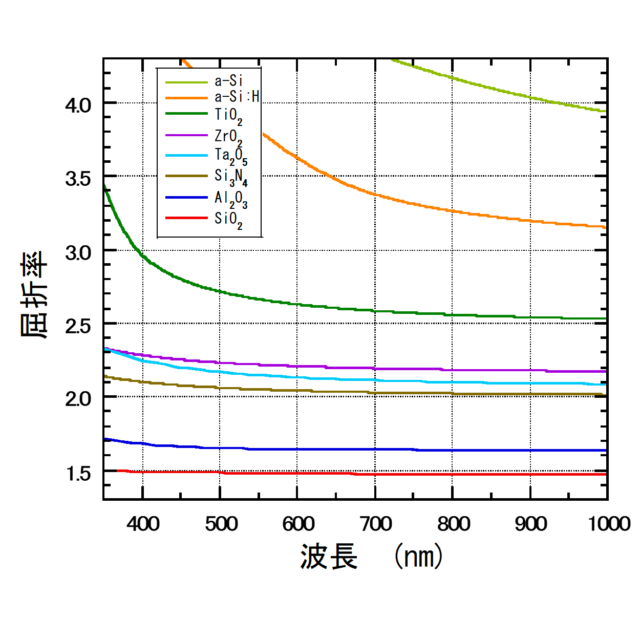

- High refractive index control

- High-speed reactive film formation

- Condensation / flat film

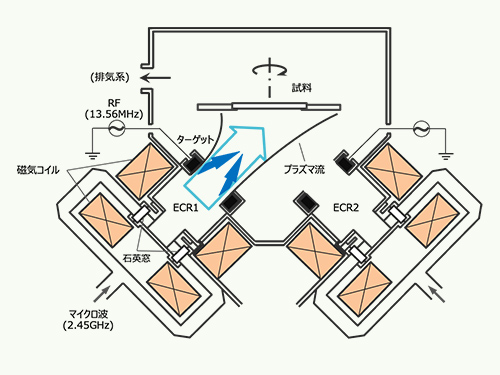

AFTEX-8000 series consists of two (2) ECR plasma sources in a process chamber and C to C automation system which forms very uniform multi-layer films onto 8 inch substrate with high quality for optical films and so on. Solid source ECR plasma deposition is achieved by high activity and high-density ECR plasma source and by putting target at pulling out plasma window.

- Deposition Characteristics

- Product Features

- Standard Specification

- Principles and Features of ECR Plasma Deposition

High quality film formation

Due to film growth under high density plasma irradiation controlled low energy of 10 – 30 eV, dense and high quality thin films having smooth at an atomic level are formed.

Multi-layer films with wide range of materials

Any solid material that can be fabricated into a sputtering target can be used as the raw material, so films of various oxides and nitrides can be formed, as well as multi-layer films, by combining them with introduced gases such as oxygen or nitrogen. For example, if Si is used as the solid source, it is possible to form SiO2, Si3N4, and Si, if Al is used as the solid source, it is possible to form Al2O3 or AlN, Besides, Ta2O5, HfO2, ZrO2, ITO, STO and so on can be formed.

Low-temperature, low-damage

Compound films such as oxide films or nitride films can be formed effect without heating by the ion-assist, high crystallinity films can be formed at low temperatures. Cleaning of the substrate with low damage can also be expected because of low ion energy.

- Two (2) ECR plasma sources in a process chamber

- Automatic Cassette to Cassette transfer system

- (up to 200 mm dia. 3 % uniformity)

- Up deposition, Facedown transfer

- Easy operation by PC, rich log functions and config tools

- SECS/GEM, CE mark, UL compliant (optional)

| Items | Specification |

|---|---|

| Ultimate pressure | Process chamber: < 3×10-5Pa Transfer chamber: < 3×10-4Pa Load-lock chamber: < 3×10-4Pa |

| Vacuum system | Process chamber: TMP 1300L/sec Dry pump: 600L/min Transfer chamber: TMP 820L/sec Dry pump: 500L/min Load-lock chamber: TMP 350L/sec Dry pump: 250L/min |

| Load-lock chamber | Manual front-door: 1 set Cassette elevator mechanism: 1 set Sample sensing mechanism: 1 set |

| Transfer chamber | Vacuum transfer robot: 1 set Sample sensing mechanism: 1 set Face-down transfer type |

| Process chamber | |

| Substrate size | Max. 8inch |

| Substrate holder | Sample stage rotation and lifting mechanism: 1 set Temporary sample receiving stage: 1 set |

| Deposition direction | Up-deposition |

| Substrate heating | Max. 300℃ |

| ECR sputtering source | |

| Quantity | 2 set |

| Plasma chamber | Microwave branching/coupling type ECR plasma source Tilted against substrate holder |

| Magnet coil | 2 split type |

| Target | Cylindrical type (with water cooling) |

| Auxiliary mechanism | Coil tilting mechanism |

| Gas feed system | Mass flow controller: 3 set Gas: Ar, O2, N2 |

| Operations | C to C full automatic processing by recipe setting (Vacuum, Transfer, Deposition) |

| Control system | Microwave power supply 2.45GHz, 1kW: 1 sets Microwave auto tuner: 2 sets Coil power supply DC1.5kW: 2 sets Sputtering power supply: 13.56MHz, 1kW: 1 set Automated RF matching unit and controller: 1 set PLC and computer: 1 set |

| Utilities | |

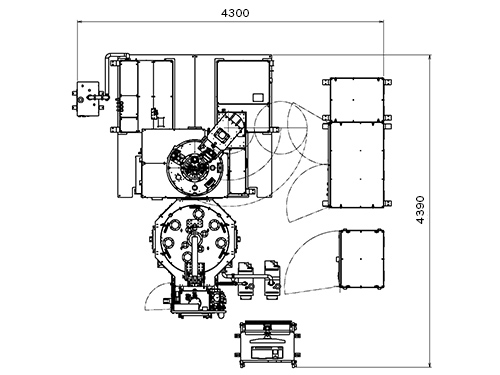

| Foot print | Approx. 5.7×4.3m (including maintenance area) |

| Electrical supply | 3-phase, 200VAC, 35KVA |

| Cooling water | 0.3~0.4MPa, 30L/min, 4 lines |

| System weight | Approx. 2600kg |

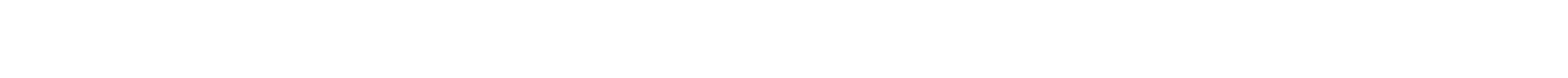

ECR Principle

High refractive index control

- No electrical power, low gas pressure (0.01-0.2 Pa), large-current ion bombardment effect at low energies (10-30 eV) to a high-density (5-10 mA/cm²) substrate surface

- Formation of precise, smooth, high-quality thin films, with low heating and low damage

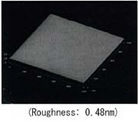

Physical properties of ECR thin films

Flatness

Hardness

SiN films and carbon films have hardnesses similar to those of diamondStrictness

Superior optical characteristics

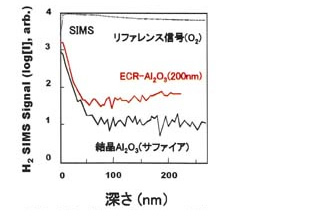

Impurity-free

High-purity target and gas used as ingredients to achieve high levels of purity with no reaction products (H, F, CI, etc.)High compoundability

Orientation of AIN films, MgO films, etc. Low-resistivity TiN films and α-Ta films.Coatability

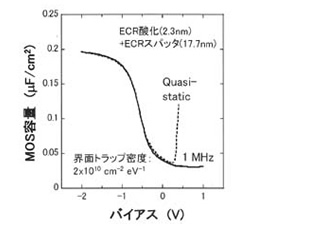

Coatability of bumps is much higher than with general sputtering, by formation of inclined rotation film at low gas pressure and high ionization rate.High voltages

High-voltage insulation film similar to bulk. 10 MV/cm for SiO2 and Al2O3 films (similar to 1000°C thermal oxidation film).Low damage

High permittivity

Formation of boundary oxide films inhibited by metal-mode depositionDrawing & Diagram

Contact Us

TEL 045-787-7203 / FAX 045-787-8472

Please feel free to contact us, you can reach us with phone or thru contact form here.