Products

System for experimental research and development

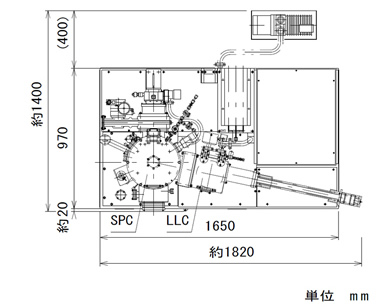

AFTEX-2300

Since this system is provided with just the basic functions of a solid source ECR plasma deposition system, it is more economical that an automatic deposition system.

- Low temperature process

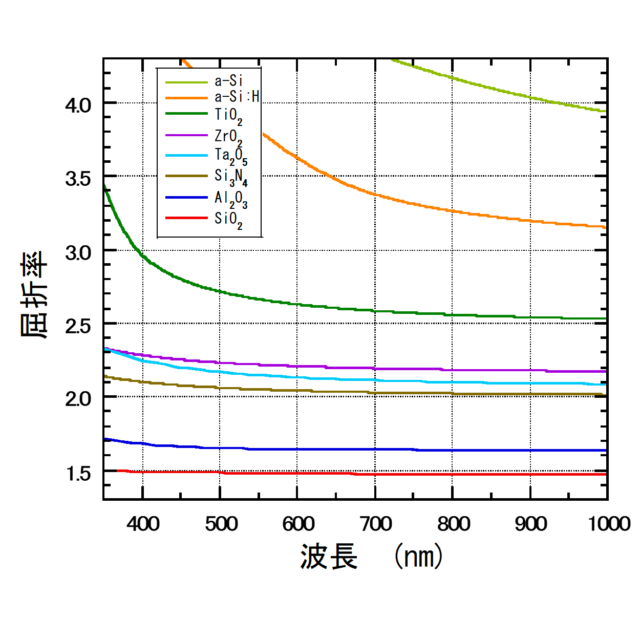

- High refractive index control

- High-speed reactive film formation

- Condensation / flat film

In answer to strong demands from those involved in thin-film research, we have developed the competitively priced AFTEX-2300. While inexpensive, it has a microwave branch coupling type of ECR ion source installed and is equipped with a load lock mechanism and turbo molecular pump, to provide top performance. This is the optimal system for research into thin films of materials such as oxides and nitrides.

- Deposition Characteristics

- Product Features

- Standard Specification

- Principles and Features of ECR Plasma Deposition

High-quality thin deposition

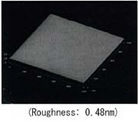

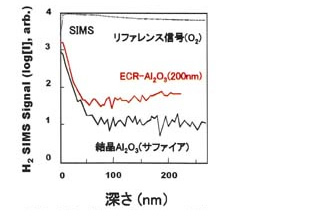

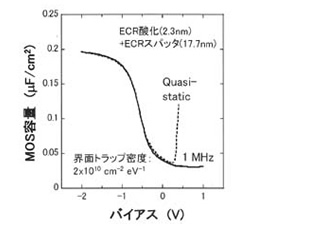

Since the thin-deposition occurs under the bombardment of high-density ions controlled at a low energy level of 10-30 eV, precise, high-quality thin films that are flat at the atomic level can be formed. In addition to SiO2 films that exhibit resistance to extreme conditions of 10 MV/cm, films of other materials can be obtained, such as Si3N4, which is as hard as diamond and has superior moisture blocking properties, and Al2O3, which provides a good barrier to hydrogen.

Low temperature, low damage

The ion-assist effect makes it possible to form thin films of chemical compounds such as oxides or nitrides without any high-temperature heating, and also makes it possible to obtain highly crystalline thin films at low temperatures. Since the ion energy is low, a soft cleaning effect with low damage to the substrate can be expected.

High-reactivity deposition

Any solid material that can be fabricated into a sputtering target can be used as the raw material, so thin films of various chemical compounds can be formed easily by combining them with introduced gases such as oxygen or nitrogen. For example, if Si is used as the solid source, Si, SiO2, and Si3N4 films can be formed, and if Al is used, Al2O3 and AlN films can be formed. We have also had results with Ta2O5, HfO2, and ZrO2 films, as well at ITO and STO films.

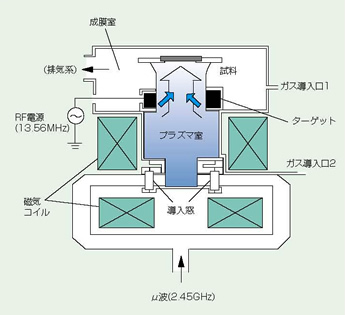

- Adhesion of films to the microwave introduction port is prevented and a branch coupling type of ECR plasma source that implements long-term stable operation is installed

- To ensure there are direct reactions between sputtering particles from the solid source and a low-energy, high-current ECR plasma flow (of oxygen or nitrogen, etc.), an environment-adapted system which makes exhaust gas processing unnecessary is used

- A clean deposition environment has been implemented by the adoption of a turbo molecular pump for the main exhaust from the deposition chamber, as well as a load lock mechanism

- The vacuum exhaust sequence is automated, and various interlock mechanisms have been adopted

| Item | Specifications |

|---|---|

| Vacuum exhaust system | Deposition chamber: TMP (450 l/s) Load lock chamber: RP (250 l/min) TMP in common |

| Deposition chamber | |

| Chamber dimensions | φ570x340mmm |

| Substrate size | 4” diameter |

| Substrate heating | Optional |

| Distance from target to substrate | 200mm |

| Load lock chamber | |

| Conveyor method | Transfer load |

| Number accommodated | 1 |

| ECR plasma source | |

| Quantity | 1 (microwave branch coupling type ) |

| Plasma chamber | φ150mm |

| Cylindrical target | φ100x40mm |

| Gas introduction lines | 2 |

| Control power source | Microwave power source (1): 2.45 GHz, 1 kW Coil power sources (2): DC 1.5 kW Target power source (1): RF 13.56 MHz |

| Operations | |

| Exhaust | Automatic |

| Substrate conveying | Automatic |

| Deposition | Automatic |

| External dimensions | 1.8×1m |

| Options | DC sputtering Substrate heating Substrate bias Additional gas introduction line possible Microwave auto-tuner |

| Performance | |

| Achieved vacuum pressure | 10-5 Pa level |

| Deposition, film thickness distribution | 3” diameter ± 10% |

| Installation conditions | |

| Electrical power | 3φ AC200V 20KVA |

| Coolant water | 10 l/min 0.3MPa |

| Weight | 1000kg |

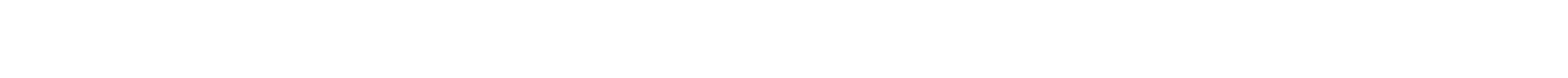

ECR Principle

High refractive index control

- No electrical power, low gas pressure (0.01-0.2 Pa), large-current ion bombardment effect at low energies (10-30 eV) to a high-density (5-10 mA/cm²) substrate surface

- Formation of precise, smooth, high-quality thin films, with low heating and low damage

Physical properties of ECR thin films

Flatness

Hardness

SiN films and carbon films have hardnesses similar to those of diamondStrictness

Superior optical characteristics

Impurity-free

High-purity target and gas used as ingredients to achieve high levels of purity with no reaction products (H, F, CI, etc.)High compoundability

Orientation of AIN films, MgO films, etc. Low-resistivity TiN films and α-Ta films.Coatability

Coatability of bumps is much higher than with general sputtering, by formation of inclined rotation film at low gas pressure and high ionization rate.High voltages

High-voltage insulation film similar to bulk. 10 MV/cm for SiO2 and Al2O3 films (similar to 1000°C thermal oxidation film).Low damage

High permittivity

Formation of boundary oxide films inhibited by metal-mode depositionDrawing & Diagram

Contact Us

TEL 045-787-7203 / FAX 045-787-8472

Please feel free to contact us, you can reach us with phone or thru contact form here.